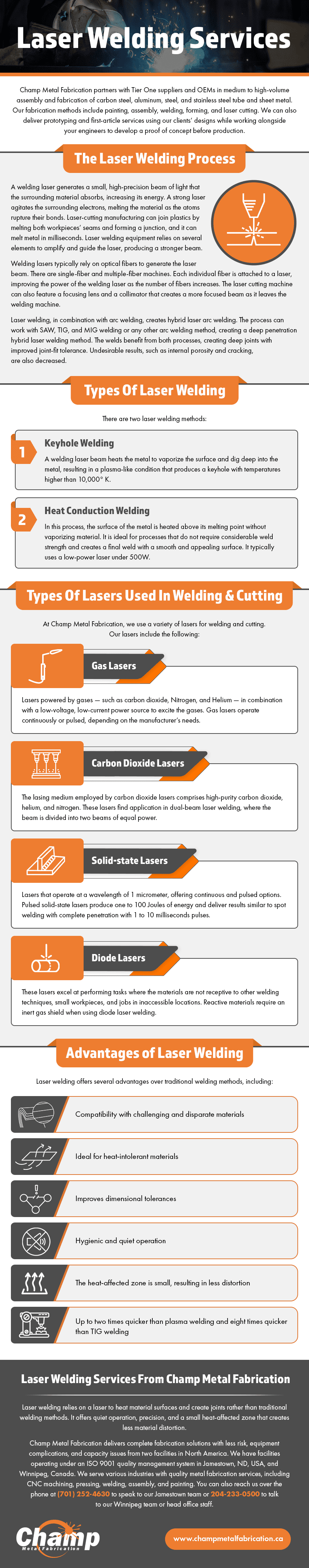

Champ Metal Fabrication partners with Tier One suppliers and OEMs in medium to high-volume assembly and fabrication of carbon steel, aluminum, steel, and stainless steel tube and sheet metal. Our fabrication methods include painting, assembly, welding, forming, and laser cutting. We can also deliver prototyping and first-article services using our clients’ designs while working alongside your engineers to develop a proof of concept before production.

The Laser Welding Process

A welding laser generates a small, high-precision beam of light that the surrounding material absorbs, increasing its energy. A strong laser agitates the surrounding electrons, melting the material as the atoms rupture their bonds. Laser-cutting manufacturing can join plastics by melting both workpieces’ seams and forming a junction, and it can melt metal in milliseconds. Laser welding equipment relies on several elements to amplify and guide the laser, producing a stronger beam.

Welding lasers typically rely on optical fibers to generate the laser beam. There are single-fiber and multiple-fiber machines. Each individual fiber is attached to a laser, improving the power of the welding laser as the number of fibers increases. The laser cutting machine can also feature a focusing lens and a collimator that creates a more focused beam as it leaves the welding machine.

Laser welding, in combination with arc welding, creates hybrid laser arc welding. The process can work with SAW, TIG, and MIG welding or any other arc welding method, creating a deep penetration hybrid laser welding method. The welds benefit from both processes, creating deep joints with improved joint-fit tolerance. Undesirable results, such as internal porosity and cracking, are also decreased.

Types Of Laser Welding

There are two laser welding methods:

- Keyhole welding: A welding laser beam heats the metal to vaporize the surface and dig deep into the metal, resulting in a plasma-like condition that produces a keyhole with temperatures higher than 10,000° K.

- Heat conduction welding: In this process, the surface of the metal is heated above its melting point without vaporizing material. It is ideal for processes that do not require considerable weld strength and creates a final weld with a smooth and appealing surface. It typically uses a low-power laser under 500W.

Types Of Lasers Used In Welding & Cutting

At Champ Metal Fabrication, we use a variety of lasers for welding and cutting. Our lasers include the following:

- Gas lasers: Lasers powered by gases — such as carbon dioxide, Nitrogen, and Helium — in combination with a low-voltage, low-current power source to excite the gases. Gas lasers operate continuously or pulsed, depending on the manufacturer’s needs.

- Carbon dioxide lasers: The lasing medium employed by carbon dioxide lasers comprises high-purity carbon dioxide, helium, and nitrogen. These lasers find application in dual-beam laser welding, where the beam is divided into two beams of equal power.

- Solid-state lasers: Lasers that operate at a wavelength of 1 micrometer, offering continuous and pulsed options. Pulsed solid-state lasers produce one to 100 Joules of energy and deliver results similar to spot welding with complete penetration with 1 to 10 milliseconds pulses.

- Diode lasers: These lasers excel at performing tasks where the materials are not receptive to other welding techniques, small workpieces, and jobs in inaccessible locations. Reactive materials require an inert gas shield when using diode laser welding.

Advantages of Laser Welding

Laser welding offers several advantages over traditional welding methods, including:

- Compatibility with challenging and disparate materials

- Ideal for heat-intolerant materials

- Improves dimensional tolerances

- Hygienic and quiet operation

- The heat-affected zone is small, resulting in less distortion

- Up to two times quicker than plasma welding and eight times quicker than TIG welding

Laser Welding Services From Champ Metal Fabrication

Laser welding relies on a laser to heat material surfaces and create joints rather than traditional welding methods. It offers quiet operation, precision, and a small heat-affected zone that creates less material distortion.

Champ Metal Fabrication delivers complete fabrication solutions with less risk, equipment complications, and capacity issues from two facilities in North America. We have facilities operating under an ISO 9001 quality management system in Jamestown, ND, USA, and Winnipeg, Canada. We serve various industries with quality metal fabrication services, including CNC machining, pressing, welding, assembly, and painting. Contact us or request a quote to learn more about our metal fabrication and laser welding capabilities.