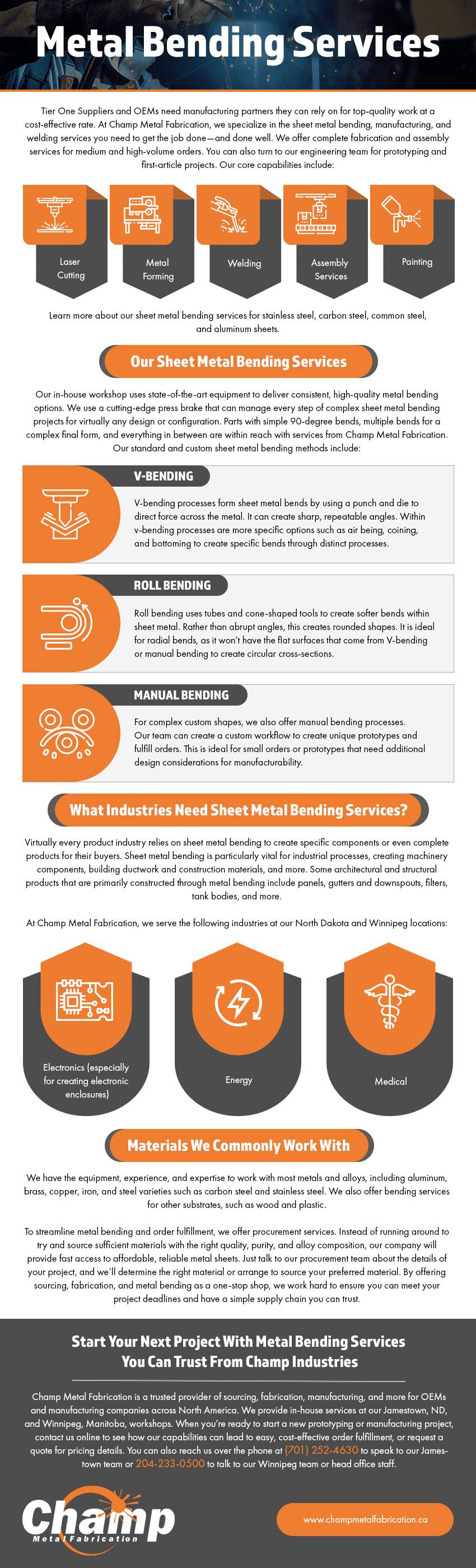

Tier One Suppliers and OEMs need manufacturing partners they can rely on for top-quality work at a cost-effective rate. At Champ Metal Fabrication, we specialize in the sheet metal bending, manufacturing, and welding services you need to get the job done—and done well. We offer complete fabrication and assembly services for medium and high-volume orders. You can also turn to our engineering team for prototyping and first-article projects. Our core capabilities include:

- Laser cutting

- Metal forming

- Welding

- Assembly services

- Painting

Learn more about our sheet metal bending services for stainless steel, carbon steel, common steel, and aluminum sheets.

Our Sheet Metal Bending Services

Our in-house workshop uses state-of-the-art equipment to deliver consistent, high-quality metal bending options. We use a cutting-edge press brake that can manage every step of complex sheet metal bending projects for virtually any design or configuration. Parts with simple 90-degree bends, multiple bends for a complex final form, and everything in between are within reach with services from Champ Metal Fabrication. Our standard and custom sheet metal bending methods include:

V-BENDING

V-bending processes form sheet metal bends by using a punch and die to direct force across the metal. It can create sharp, repeatable angles. Within v-bending processes are more specific options such as air being, coining, and bottoming to create specific bends through distinct processes.

ROLL BENDING

Roll bending uses tubes and cone-shaped tools to create softer bends within sheet metal. Rather than abrupt angles, this creates rounded shapes. It is ideal for radial bends, as it won’t have the flat surfaces that come from V-bending or manual bending to create circular cross-sections.

MANUAL BENDING

For complex custom shapes, we also offer manual bending processes. Our team can create a custom workflow to create unique prototypes and fulfill orders. This is ideal for small orders or prototypes that need additional design considerations for manufacturability.

What Industries Need Sheet Metal Bending Services?

Virtually every product industry relies on sheet metal bending to create specific components or even complete products for their buyers. Sheet metal bending is particularly vital for industrial processes, creating machinery components, building ductwork and construction materials, and more. Some architectural and structural products that are primarily constructed through metal bending include panels, gutters and downspouts, filters, tank bodies, and more.

At Champ Metal Fabrication, we serve the following industries at our North Dakota and Winnipeg locations:

- Electronics (especially for creating electronic enclosures)

- Energy

- Medical

Materials We Commonly Work With

We have the equipment, experience, and expertise to work with most metals and alloys, including aluminum, brass, copper, iron, and steel varieties such as carbon steel and stainless steel. We also offer bending services for other substrates, such as wood and plastic.

To streamline metal bending and order fulfillment, we offer procurement services. Instead of running around to try and source sufficient materials with the right quality, purity, and alloy composition, our company will provide fast access to affordable, reliable metal sheets. Just talk to our procurement team about the details of your project, and we’ll determine the right material or arrange to source your preferred material. By offering sourcing, fabrication, and metal bending as a one-stop shop, we work hard to ensure you can meet your project deadlines and have a simple supply chain you can trust.

Start Your Next Project With Metal Bending Services You Can Trust From Champ Industries

Champ Metal Fabrication is a trusted provider of sourcing, fabrication, manufacturing, and more for OEMs and manufacturing companies across North America. We provide in-house services at our Jamestown, ND, and Winnipeg, Manitoba, workshops. When you’re ready to start a new prototyping or manufacturing project, contact us online to see how our capabilities can lead to easy, cost-effective order fulfillment, or request a quote for pricing details. You can also reach us over the phone at 701-252-4630 to speak to our Jamestown team or 204-233-0500 to talk to our Winnipeg team or head office staff.