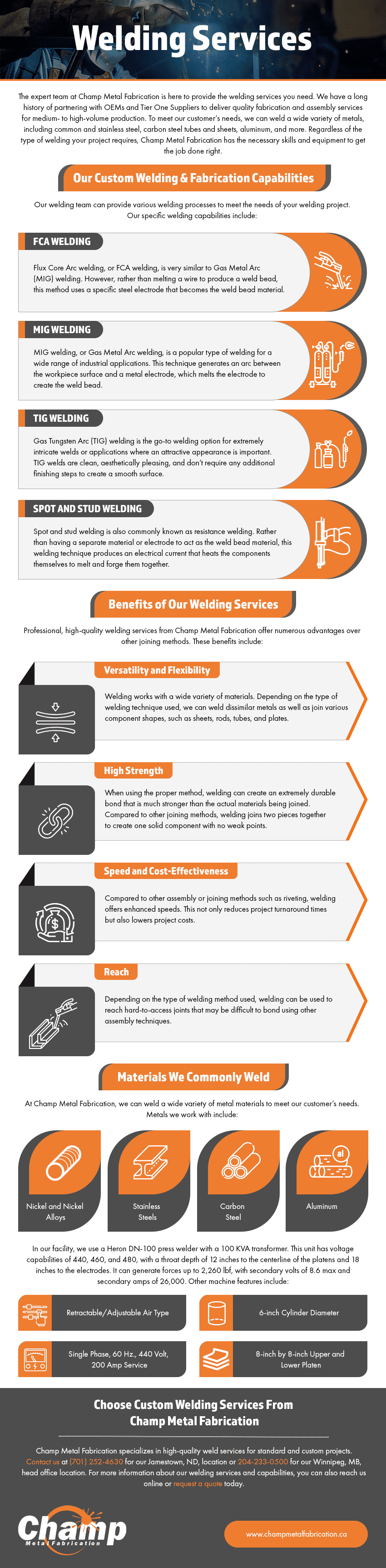

The expert team at Champ Metal Fabrication is here to provide the welding services you need. We have a long history of partnering with OEMs and Tier One Suppliers to deliver quality fabrication and assembly services for medium- to high-volume production. To meet our customer’s needs, we can weld a wide variety of metals, including common and stainless steel, carbon steel tubes and sheets, aluminum, and more. Regardless of the type of welding your project requires, Champ Metal Fabrication has the necessary skills and equipment to get the job done right.

Our Custom Welding & Fabrication Capabilities

Our welding team can provide various welding processes to meet the needs of your welding project. Our specific welding capabilities include:

FCA WELDING

Flux Core Arc welding, or FCA welding, is very similar to Gas Metal Arc (MIG) welding. However, rather than melting a wire to produce a weld bead, this method uses a specific steel electrode that becomes the weld bead material.

MIG WELDING

MIG welding, or Gas Metal Arc welding, is a popular type of welding for a wide range of industrial applications. This technique generates an arc between the workpiece surface and a metal electrode, which melts the electrode to create the weld bead.

TIG WELDING

Gas Tungsten Arc (TIG) welding is the go-to welding option for extremely intricate welds or applications where an attractive appearance is important. TIG welds are clean, aesthetically pleasing, and don’t require any additional finishing steps to create a smooth surface.

SPOT AND STUD WELDING

Spot and stud welding is also commonly known as resistance welding. Rather than having a separate material or electrode to act as the weld bead material, this welding technique produces an electrical current that heats the components themselves to melt and forge them together.

Benefits of Our Welding Services

Professional, high-quality welding services from Champ Metal Fabrication offer numerous advantages over other joining methods. These benefits include:

- Versatility and Flexibility: Welding works with a wide variety of materials. Depending on the type of welding technique used, we can weld dissimilar metals as well as join various component shapes, such as sheets, rods, tubes, and plates.

- High Strength: When using the proper method, welding can create an extremely durable bond that is much stronger than the actual materials being joined. Compared to other joining methods, welding joins two pieces together to create one solid component with no weak points.

- Speed and Cost-Effectiveness: Compared to other assembly or joining methods such as riveting, welding offers enhanced speeds. This not only reduces project turnaround times but also lowers project costs.

- Reach: Depending on the type of welding method used, welding can be used to reach hard-to-access joints that may be difficult to bond using other assembly techniques.

Materials We Commonly Weld

At Champ Metal Fabrication, we can weld a wide variety of metal materials to meet our customer’s needs. Metals we work with include:

- Nickel and nickel alloys

- Stainless steels

- Carbon steel

- Aluminum

Our Welding Machines

In our facility, we use a Heron DN-100 press welder with a 100 KVA transformer. This unit has voltage capabilities of 440, 460, and 480, with a throat depth of 12 inches to the centerline of the platens and 18 inches to the electrodes. It can generate forces up to 2,260 lbf, with secondary volts of 8.6 max and secondary amps of 26,000. Other machine features include:

- Retractable/Adjustable Air Type

- 6-inch Cylinder Diameter

- Single Phase, 60 Hz., 440 Volt, 200 Amp Service

- 8-inch by 8-inch Upper and Lower Platen

In addition to our Heron DN-100 press welding machine, we also use a Techna 4662 Programmable Rocker Arm Welder as well as various TIG and MIG welding stations and a tensile strength tester up to 20,000 lbs.

Choose Custom Welding Services From Champ Metal Fabrication

Champ Metal Fabrication specializes in high-quality weld services for standard and custom projects. Contact us at (701) 252-4630 for our Jamestown, ND, location or 204-233-0500 for our Winnipeg, MB, head office location. For more information about our welding services and capabilities, you can also reach us online or request a quote today.